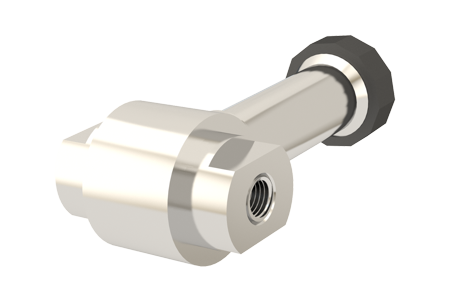

High-precision, wet/wet differential pressure transmitter - Model PN2M

Product description

Featuring a state-of-the-art digital compensation and two pressure ports for high and low pressures, the PN2M model has been designed to measure low to medium differential pressures under extreme line pressure (up to 600 bar). This wet/wet differential pressure transmitter utilizes the latest leading-edge technologies to provide high accuracy and high precision pressure measurement and offers unequaled performance, excellent stability and proven reliability.

The sensor integrates a single solid-state, piezoresistive MEMS silicon die which acts as the sensitive element and converts pressure into an electrical signal. Using advanced techniques of MEMS fabrication (like wet etching, anisotropic etching), a thin diaphragm is crafted inside the silicon die. The thickness of the diaphragm is individually adapted to each pressure range so as to get the highest possible sensitivity without breaking under full pressure load.

The sensor signal is digitized, compensated and processed by a powerful, low power 32-bit microcontroller. It is then converted back to an amplified analog signal. The digital electronics ensures precise calibration of all critical parameters and achieves very high precision, thermal stability and compensation of all repeatable errors. Each unit is fully tested, compensated and calibrated for pressure and temperature. Each transmitter is shipped with a traceable calibration card.

The electronic circuit is packaged in a hermetically-sealed, all-welded 316L stainless steel housing enabling the PN2M to be immersed in water or pressure washed without internal leakage. This design makes the PN2M ideal for pressure measurements that can involve wet, corrosive or sterile media in the most severe environments.

Specifications

| Physical characteristics | |

|---|---|

| Pressure range | 0 to 2 bar through 0 to 20 bar |

| Safe overpressure | 2 x (positive side), 1.5 x (negative side) |

| Burst pressure | 3 x (positive side), 2 x (negative side) |

| Line pressure | 600 bar |

| Environmental characteristics | |

|---|---|

| Storage temperature | -40 to 125°C |

| Operating temperature extremes | -40°C, 125°C |

| Maximum operating temperature span | 140°C |

| Ambient temperature | -40 to 80°C |

| Electrical characteristics (choose one circuit) | ||||

|---|---|---|---|---|

| Power supply / excitation | 8 - 32 VDC | 13 - 32 VDC | 8 - 32 VDC | 8 - 32 VDC |

| Output signal | 4 - 20 mA | 0 - 10 VDC | 0 - 5 VDC | 0.5 - 4.5 VDC |

| Current draw | 20 mA | 5 mA | 5 mA | 4 mA |

| Response time | 5 ms | 5 ms | 5 ms | 5 ms |

| Mechanical characteristics | |

|---|---|

| Electrical connections | ✔ DIN 43650-A ✔ Amphenol C 091 A ✔ M12x1 ✔ PTIH-10-6P ✔ PE cable |

| Mechanical connections | ✔ G 1/4" Int ✔ 1/4"-18NPT Int |

| Materials available | 316L Stainless steel |

| Seal materials available | FKM, EPDM, Silicone, NBR |

| Performance (depending on temperature compensation range) | |

|---|---|

| Compensated temperature range | -10 to 80°C |

| Linearity | ±0.02%FS |

| Hysteresis | ±0.005%FS |

| Repeatability | ±0.005%FS |

| Line pressure drift | ±0.005 %FS/bar |

| Zero offset | ±2mV |

| Span offset | ±0 |

| Temperature drift of Zero | ±0.01%FS/K |

| Temperature drift of Sensitivity | ±0.03%/K |

| Stability (per annum) | ±0.1%FS |

All values are typical values.