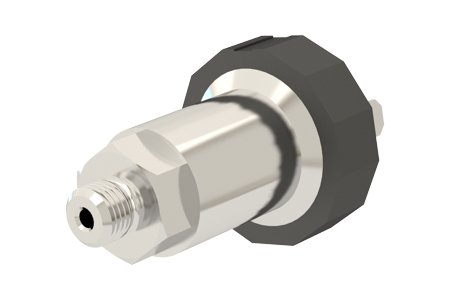

Industrial pressure transmitter - Model PI3M

Product description

Senzors’ model PI3M is an advanced, digitally compensated pressure transmitter which provides high accuracy and cost-effectiveness in one package. Equipped with the latest leading-edge technologies, it offers high precision, excellent stability and proven reliability in a compact, rugged design. It is the perfect solution for any application that requires a highly accurate, low to medium pressure measurement. Its modular design makes it a general-purpose industrial pressure transducer that can serve as the basis for a unique custom solution without sacrificing price and high performance.

The sensing element is a solid-state piezoresistive silicon die. This technology is based on a principle that results in excellent linearity, increased long-term stability and reliability and virtually no hysteresis. The silicon strain gage is fitted into a 316 stainless steel package and is completely isolated from the media. There are no internal O-rings or elastomers to contain the media and to contribute to instabilities or drifts.

The sensor signal is digitized, compensated and processed by a powerful, low power 32-bit microcontroller. It is then converted back to an amplified analog signal. The digital electronics ensures precise calibration of all critical parameters and achieves very high precision, thermal stability and compensation of all repeatable errors. Each unit is fully tested, compensated and calibrated for pressure and temperature. Each transmitter is shipped with a traceable calibration card.

The electronics is packaged in a hermetically-sealed all-welded 316 stainless steel housing enabling the PI3M to be immersed in water or pressure washed without internal leakage. This design makes the PI3M ideal for pressure measurements that can involve wet, corrosive or sterile media in the most severe environments.

Specifications

| Physical characteristics | |

|---|---|

| Pressure range | 0 to 2 bar through 0 to 20 bar |

| Pressure type | ✔ absolute ✔ vented gage ✔ sealed gage ✔ compound |

| Vacuum | possible, down to 1 μbar absolute |

| Safe overpressure | 1.5 x |

| Burst pressure | 2 x |

| Environmental characteristics | |

|---|---|

| Storage temperature | -40 to 125°C |

| Operating temperature extremes | -40°C, 125°C |

| Maximum operating temperature span | 160°C |

| Ambient temperature | -40 to 80°C |

| Electrical characteristics (choose one circuit) | ||||

|---|---|---|---|---|

| Power supply / excitation | 8 - 32 VDC | 13 - 32 VDC | 8 - 32 VDC | 8 - 32 VDC |

| Output signal | 4 - 20 mA | 0 - 10 VDC | 0 - 5 VDC | 0.5 - 4.5 VDC |

| Current draw | 20 mA | 5 mA | 5 mA | 4 mA |

| Response time | 5 ms | 5 ms | 5 ms | 5 ms |

| Mechanical characteristics | |

|---|---|

| Electrical connections | ✔ DIN 43650-A ✔ Amphenol C 091 A ✔ M12x1 ✔ PTIH-10-6P ✔ PE cable |

| Mechanical connections | ✔ G 1/4" Ext ✔ G 1/4" Int ✔ G 1/2" Ext ✔ G 1/2" Ext ✔ 1/4"-18NPT Ext |

| Materials available | 316L Stainless steel |

| Seal materials available | FKM, EPDM, Silicone, NBR |

| Performance (depending on temperature compensation range) | ||

|---|---|---|

| Compensated temperature range | 0 to 50°C | -10 to 80°C |

| Linearity | ±0.05%FS | ±0.05%FS |

| Hysteresis | ±0.005%FS | ±0.005%FS |

| Repeatability | ±0.005%FS | ±0.005%FS |

| Zero offset | ±2mV | ±2mV |

| Span offset | ±0 | ±0 |

| Temperature drift of Zero | ±0.01%FS/K | ±0.01%FS/K |

| Temperature drift of Sensitivity | ±0.03%/K | ±0.03%/K |

| Stability (per annum) | ±0.1%FS | ±0.1%FS |

All values are typical values.